WAVE

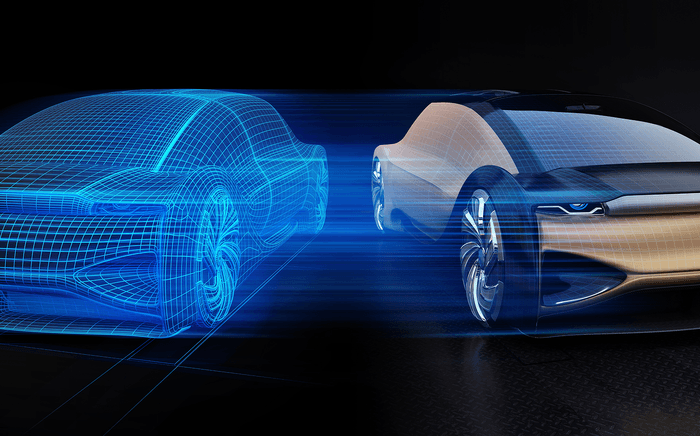

WAVE and its faster than real-time component WAVE-RT are at the forefront of 1D CFD technology for the analysis of Internal Combustion Engines (ICE). Our approach, combining precision and user friendliness, empowers engineers globally to forge intricate digital engine twins that epitomize design concepts. This capability proves invaluable for tasks such as analysis, optimisation, calibration, diagnostics, and maintenance of IC engines. Prioritising the precision of simulation and including targeted capabilities aimed at sustainable and non-carbon fuel modelling, WAVE finds applications across diverse industrial sectors such as automotive, aerospace, rail, motorsport, maritime, and power generation. The paramount commitment of WAVE to customer satisfaction propels the transition towards virtual product development, enabling engineers to embrace cutting-edge innovations and accelerated R&D, all while curbing development costs.

WAVE is the technology leader in 1D engine plant model analysis supporting a wide range of applications. From concept studies to detailing engine performance and cooling system inputs, from optimisation of engine components to acoustic analysis and noise level optimisation; from fuel composition sensitivity to fault analysis and maintenance - WAVE can provide accurate answers to complex questions facing engineering analysis teams.

WAVE-RT is the industry’s leading faster than real-time engine plant modelling solver. Created from WAVE models with a single click export, it has been developed for fast comprehensive virtual calibration and validation. WAVE-RT is used to model advanced control strategies that need to be designed, tested and validated for integration into new engine control units. Furthermore, current generation WAVE-RT has fidelity approaching full 1D CFD modelling and can provide a drop-in engine plant replacement in many pre-development tasks, such as transmission calibration. Calibrated WAVE-RT engine plant models also enable system level simulations for applications such as digital monitoring, fault analysis, drivability and OBD system improvement in Model-in-the-Loop, Software-in-the-Loop and Hardware-in-the-Loop environments.

Key features

The WAVE product suite plays a pivotal role throughout the entire engine life cycle, improving the way we design, develop, and maintain engines. From inception to operation and maintenance, WAVE seamlessly integrates into your workflow, delivering unmatched precision and efficiency. From the initial design stages, encompassing performance and component design, control systems development through virtual calibration, and comprehensive performance verification for IC engines, powertrains, and finally - delivering the accurate real-time heart for complete vehicle simulation environments.

Going beyond engine design and production, WAVE and its faster than real-time WAVE-RT engine model helps our customers enhance engine operation and maintenance workflows enabling fault detection and online performance monitoring based on digital twin technology.

Our customers across diverse sectors benefit from WAVE's unparalleled usability and accuracy, spanning the spectrum of Internal Combustion Engines. From compact utility engines to maritime and power generation giants WAVE equips our customers to tackle pressing challenges in today's business landscape.

From cost optimisation, performance enhancement, and emissions reduction to embracing hybridisation, synthetic fuels, and achieving overall carbon neutrality.

Be at the centre of decision making

At Realis, we understand that each customer is unique and we are offering a close partnership helping our customers build tailored solutions and processes reflecting their workflows and maximizing efficiency of their CAE process. We put our customers in the centre of decision making by offering :

- Direct interaction with product and development teams through customer driven product development

- Bespoke model development and rapid enhancement development based on customer feedback

- Early access to requested features through customized software versions

- Dedicated and tailored support, customized interactive training

- Process and model building consulting services

- Tailored licensing solutions

Our insights

CFD and FE Toolset for Predicting Structural Temperatures in a Hydrogen Internal Combustion Engine

Technical Paper

Cloud HPC and data-driven engineering pave the way for next-generation research and development

Conference

An introduction to R-Post

Video

Biofuel Concentration in Low-Speed Pre-Ignition in Gasoline Engines

Technical Paper