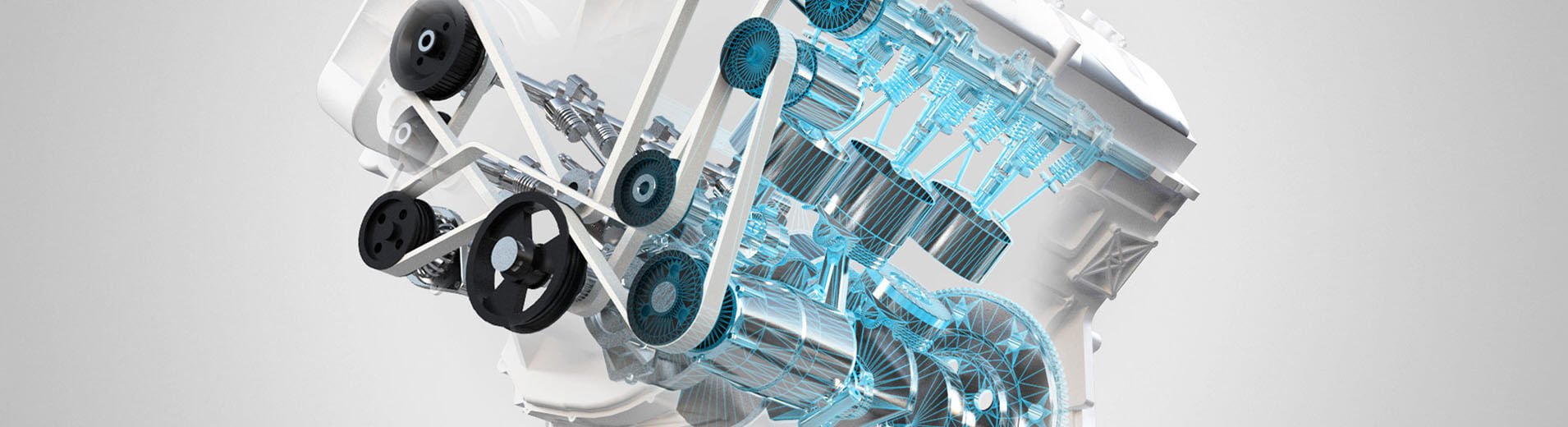

ENGDYN - bearing analysis

ENGDYN directly couples the crankshaft and cylinder-block dynamics with the bearing oil film to allow the user to perform a range of analyses to aid bearing design. ENGDYN incorporates a hierarchy of solution methods, from the industry standard mobility method through to more rigorous hydrodynamic (HD) and elastohydrodynamic (EHD) models. Whether early in a programme, when only concept-level models are available, or when detailed studies are required, ENGDYN provides the tools for the engineer to assess bearing performance.

Specific bearing applications

- Bearing-type selection

- Bearing durability

- Friction and mass-flow calculations

- Load transfer to powertrain

Key features

- Direct coupling of crankshaft and crankcase dynamics with bearing

- Mass-conserving hydrodynamic-lubrication modelling

- Boundary lubrication modelling

- Thermal-balance modelling

- Viscosity-pressure and viscosity-temperature dependence

- Compressible flow to include effect of oil aeration