Delivering IMO emission targets

Delivering IMO emission targets

Simulation of combustion, temperature and emissions for Internal Combustion Engines (ICE) will play an important role in delivering emission targets set by the International Maritime Organisation (IMO)1. A number of alternatives to fossil fuels for maritime ICE exist, including biofuel and methanol carbon-neutral fuels, as well as zero-carbon ammonia and hydrogen which use SI combustion for ammonia-hydrogen blends and CI combustion for ammonia-diesel dual-fuel. Each fuel option offer different challenges in terms of energy density, bunkering and safety.

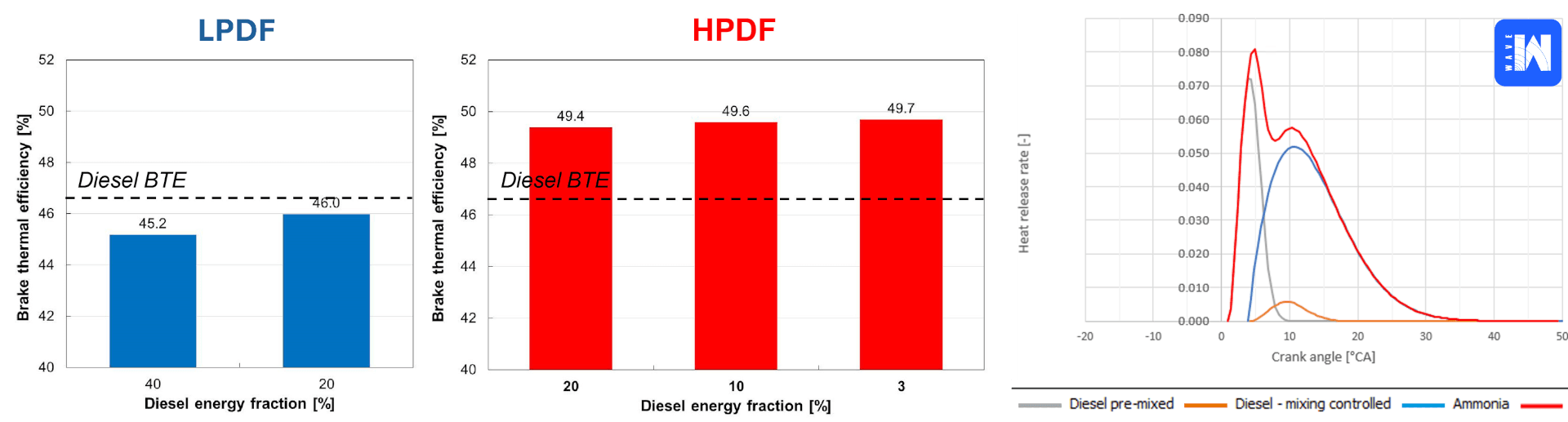

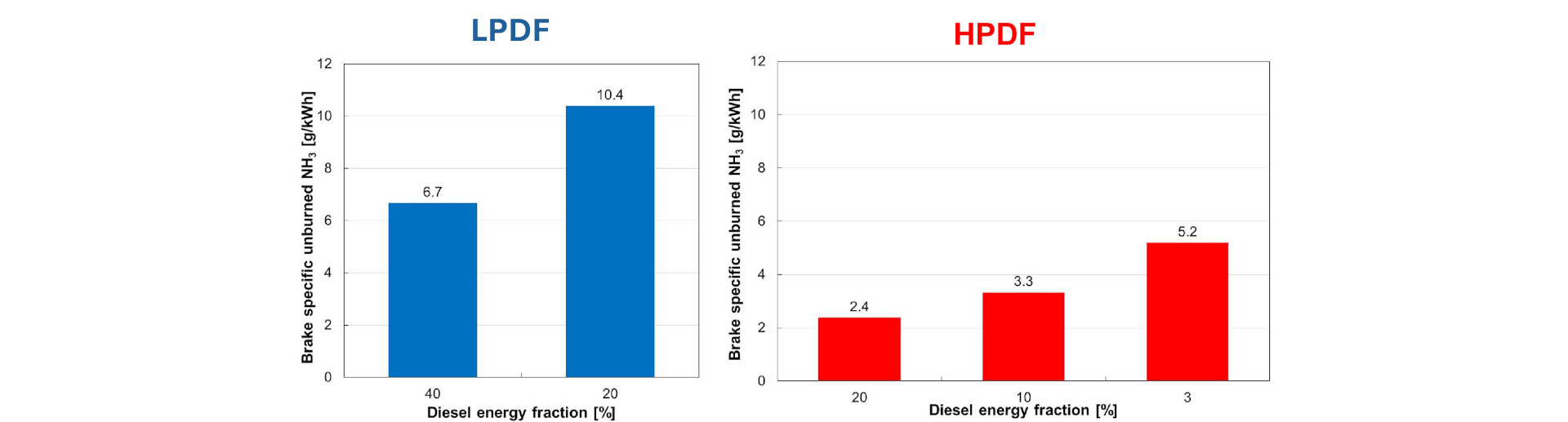

'High-Pressure Dual-Fuel Combustion Systems for Sustainable Maritime Engines', Ricardo, MariNH3 Conference 2025

CFD is used to investigate different fuel with different blends to predict performance, thermal efficiency, pollutant and greenhouse gas (GHG) emissions and fuel slip. In addition, FEARCE-Vulcan provides a unique 3D FE thermal model of the power cylinder using physical models and semi-empirical correlations to predict in-cylinder temperatures arising from CI and SI combustion of different fuel types. In 1D-CFD WAVE the Multi-Weibe combustion model is used to calculate the burn-rate of combined fuels, with VECTIS 3D-CFD used to model High Pressure Dual Fuel (HPDF) combustion systems requiring high-pressure multi-fuel injectors to achieve late injection of both diesel and liquid ammonia.

‘A comparison between low- and high-pressure injection dual-fuel modes of diesel-pilot-ignition ammonia combustion engines', Li et al. (2022)

Detailed chemistry is crucial in ICE simulations to capture fuel composition effects and pollutant formation. VECTIS 3D-CFD uses a unique chemical clustering method that accelerates solution times enabling practical, high-fidelity fuel and emissions modelling.

© Copyright SAE 2023-01-1603

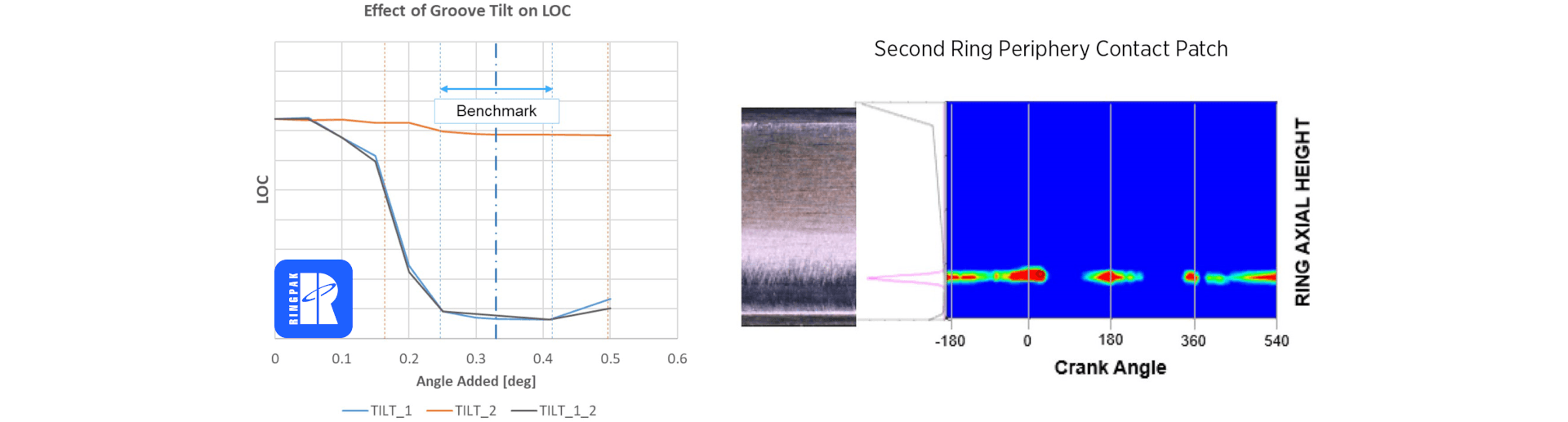

A further source of emissions arises from lubricant oil that passes the top-ring into the combustion chamber. The RINGPAK 3-piece Oil Control Ring (OCR) model uses 3 separate bodies to accurately capture the dynamic interactions between each body. Combining with an oil transport model which evaluates the oil flows that sweep the piston crown surfaces driven by oil inertia , means that the piston ring pack can be optimised to minimise Lubricant Oil Consumption (LOC) and emissions.

FEARCE-Vulcan uses a unique iterative Finite Element solution that considers all the heat paths in detail to deliver a reliable and accurate predictive tool for conclusive structural investigations.

RINGPAK is an advanced 2D simulation package which enables users to predict and optimise ring pack dynamics, lubrication, gas flow and oil consumption using both steady state and transient models.

WAVE is a 1D Computational Fluid Dynamics (CFD) that solves the Navier-Stokes equations governing the transfer of mass, momentum, and energy for compressible gas flows, and includes sub-models for combustion and emissions.

VECTIS is a 3D CFD tool that uses cutting edge chemical kinetics, flame propagation and emissions models for conventional hydrocarbons, biofuels, methanol, ammonia-hydrogen blends and ammonia-diesel dual-fuel.

1 2023 IMO Strategy on Reduction of GHG Emissions from Ships, Resolution MEPC.377(80) Annex 1

Our insights

CFD and FE Toolset for Predicting Structural Temperatures in a Hydrogen Internal Combustion Engine

Technical Paper

Calculation of Thermal Boundary Conditions for Hydrogen Internal Combustion Engines

Technical Paper

Thermo-Diffusive Flame Speed Adjustment and its Application to Hydrogen Engines

Technical Paper