Commercial vehicle

Driving sustainable heavy duty vehicle transportation

In today's market with increasing emissions regulations aiming for a net zero future, the heavy-duty commercial transport industry is under pressure to reduce carbon emissions with such a large part of the global economy relying on the road transportation of goods and mass movement of people in buses and coaches. Commercial vehicle manufacturers now need to balance the optimisation of existing engines with lower emissions and increased fuel economy as well as introduce new non-carbon technology.

The design challenge, using simulation, is to consider all the available the options across full electric, hybrid, hydrogen fuel cells, ammonia and hydrogen combustion as well as e-fuel viability.

In the initial stages of development, physical prototype modelling is expensive, requiring virtual simulation tools to answer many of the 'What ifs' before committing to a design path. The propulsion system simulation is at the heart of truck and coach design where, predicting performance across a range of applications will be essential to select the correct propulsion system for the correct application going forward.

At Realis Simulation we have extensive experience of using software to streamline the propulsion system design process – answering many of the ‘What ifs’ using computer simulation before Original Equipment Manufacturers (OEMs) and Tier 1 suppliers commit to expensive physical prototypes.

Our software analyses the full heavy-duty vehicle system design from fuel intake, power generation, power transfer and exhaust emissions reduction. It simulates energy losses from friction, oil consumption and thermal heat transfer as well as component durability across various drive cycles using traditional, non-carbon e-fuels, hybrid, electric, hydrogen fuel cells and hydrogen combustion power units.

Our insights

CFD and FE Toolset for Predicting Structural Temperatures in a Hydrogen Internal Combustion Engine

Technical Paper

Biofuel Concentration in Low-Speed Pre-Ignition in Gasoline Engines

Technical Paper

Calculation of Thermal Boundary Conditions for Hydrogen Internal Combustion Engines

Technical Paper

Clean combustion modelling

Brochure

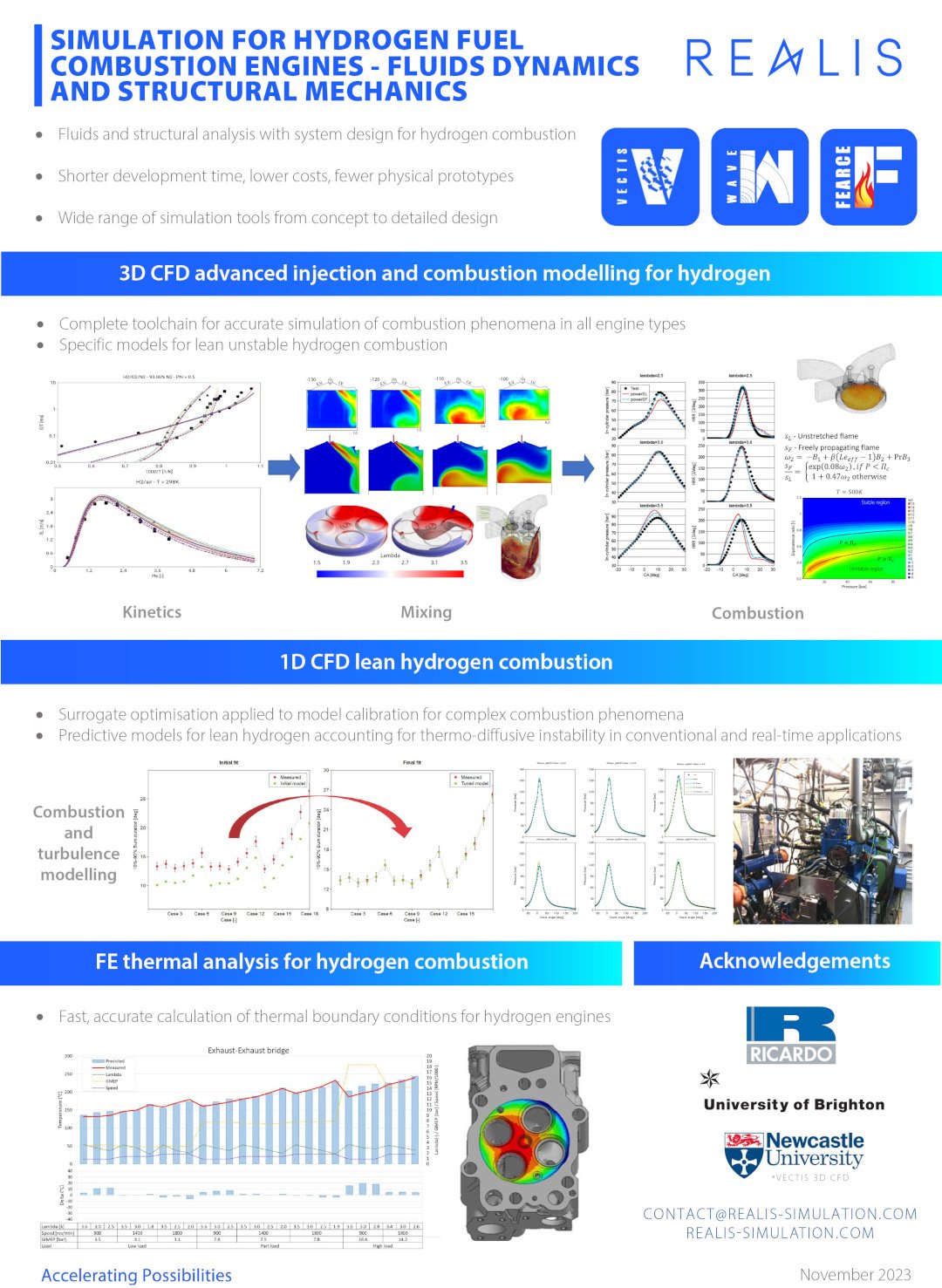

Hydrogen combustion

Brochure

Thermo-Diffusive Flame Speed Adjustment and its Application to Hydrogen Engines

Technical Paper

Application of Miller Cycle and Net-Zero Fuel(s) to Diesel Engine: Effect on the Performance and NOx Emissions of a Single-Cylinder Engine

Technical Paper